Solutions for the cement industry

NOx-reduction in the cement industry are complex. Requirements are demanding not only on reduction in NOx but also in added ammonia to the flue gas together with elimination of the potential risk of enhanced CO-emissions as well as inter activated formation of N2O.

ABC&I´s products in the field of NOx-reduction encompass four different methodologies. The first alternative uses a mathematical modelling method in which combustion-controlling parameters are optimised in such a combination that the NOx-formation is steered to a minimum level. Used mathematical tools are CFD – and/or multivariate analysis. A typical optimisation normally leads to a NOx reduction between 10-30% depending on the complexity in the combustional system. The higher the complexity, the higher potential of NOx-reduction. Constraints are CO-level and clinker quality.

The second methodology suppresses the NOx formation in the burner flame. The kiln burner is modified with an added equipment and control system. Two additional combustion-influencing parameters are introduced in order to minimise the NOx-reduction in the flame. The media costs are low. Typical NOx-reduction is lying in the interval of 20-30%. In combination with an SNCR-system (Selective Non Cathalytic NOx-Reduction) this technology is also diminishing the chemical consumption of the reduction agent.

The third and fourth methodologies are building on chemical NOx-reduction by means of a nitrogen based reduction agent e.g. ammonia. Used technologies are SNCR- or SCR- systems (Selective Cathalytic NOx-Reduction). Due to lack of cost efficiency, SCR has so far not been used in the context of cement manufacturing in ABC&I led projects.

Environmental benefits

Lessened NOx-emissions to atmosphere are lowering negative impacts on the receiving eco system. The most pronounced are:

- Acid rain

- Ozone formation on ground level

- Nitrogen outlet to the marine eco system

NOx-formation in the kiln burner zone

NOx sources are:

a. Thermal NOx-dominating at high temperatures in the burner zone

b. Fuel nitrogen NOx - stemming from the nitrogen content in the fuel

c. Prompt NOx - small contribution in the context of cement clinker production

Thermal NOx-formation and clinker production constraints

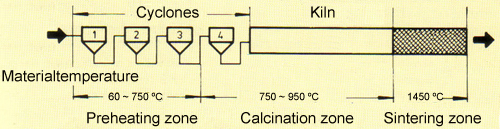

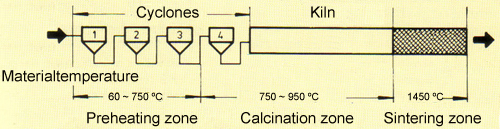

Gas temperatures in the burnerflame zone are normally 2100ºC - 2300ºC in order to accomplish a full clinker "burning" reaction, clinker temperature needs to exceed 1400ºC.

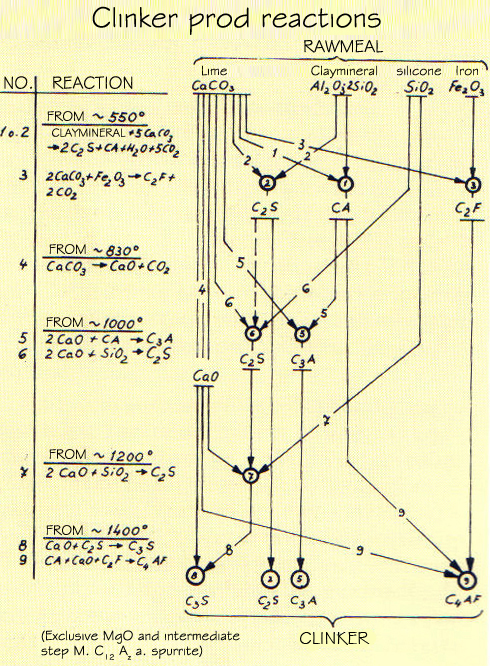

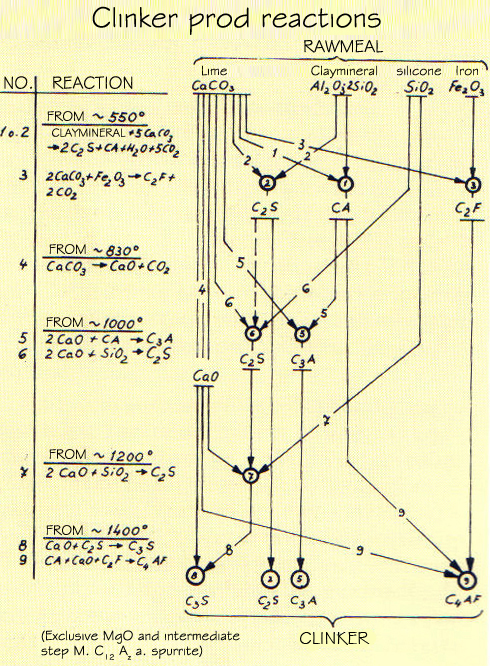

Reactions and reaction temperatures in the clinker production process are as follows:

| Clinkermineral |

Chemical formula |

Cement chemical

formula |

Tricalciumsilicate

Dicalciumsilicate

Tricalciumaluminate

Brown-Millerit |

3(CaO) - SiO2

2(CaO) - SiO2

3(CaO) - A12O3

4(CaO) - A12O3- Fe2O2

|

C2S

C2S

C3A

C4AF |

Used deNOx chemicals

The most potent reduction agents for the NOx-reduction are normally nitrogen based. For best performance, the selected chemical for NOx-reduction should be made from the basis of the specific operational conditions in the kiln/precalciner/preheater system. ABC&I provides deNOx- reduction options in respect to all commercial available reduction agents. Based on the properties of the cement production system, the most appropriate reduction agent is selected. ABC&I have vast experience from excisting reference plants where different chemicals have shown to produce the most optimal results in different types of cement production plants.

Investment costs- Non catalytic NOx-reduction

Investment costs are comparatively low in respect to other measures against emissions such as dust or technologies based on catalysis or scrubber absorption.

Chemical costs

Cost of chemicals is the most dominating factor in reducing NOx-emissions. Selecting the best technology is much a question of chemical use efficiency. A low technology based NOx-reduction could require twice the quantity of the chemicals for a specific set NOx-emission level. Depending on production capacity of the cement plant this may lead to extra chemical costs in the range of several hundreds of thousands euro per year.

Potential impact on the cement producing system

Used reduction agents are potent chemicals and must be treated in accordance with normal chemical processing procedures. The equipments used for NOx-reduction must have high enough standard in respect to chemical risk exposure as well as resist destructive forces from high temperatures (ca 1000ºC), abrasive impact of raw meal and a highly corrosive flue gas with sticking prone components. The NOx-reducing equipments must also stand the aggressive environment after many years of operation, giving a safe and reliable operation in respect to NOx-reduction and to the cement production plant.

The most appropriate NOx-reduction method is selected depending on type of cement production plant and requirements put on NOx, NH3-slipp, operational costs etc. A vast number of deNOx projects delivered to the cement industry makes the ABC&I company to a leading supplier in this highly specialized field.

|